Post by silveryaker on Sept 13, 2012 18:28:20 GMT -5

I started by looking at what Elgeebee on SCKF did, what Jackson Kayak recommended on their website and what Lowrance sold online for scupper hole transducer installation to get my inspiration. I didn’t like the Lowrance set-up because it was too much plastic and too much money. I couldn’t find stainless steel bar and didn’t want to use aluminum flat bar like Elgeebee did (didn’t know how long it would hold up in salt water). So, I came up with a design that copied elements of all three designs for less than $10 in parts and some leftover odds and ends from other jobs. Here’s what I did.

Parts

1 – Lowrance transom mount transducer

1 – Lowrance transom mounting bracket

1 – Set Lowrance bolt, nut & washers for transducer to bracket connection

1 – ¼-20x5” SS carriage bolt ($1.98 – Lowes)

1 – ½x2 SS fender washer ($0.65 – Lowes)

1 – ¼x1¼ SS fender washer ($0.65 – Lowes)

1 – ¼-20 SS nylon lock nut ($1.18 for 3 – Home Depot)

1 – Leftover Rainbird superpipe (~ ½ in. dia. x 2 1/8 in. long plastic – free)

1 – Blue pool noodle (~$2.00 – Walmart)

1 – Rubber grommet (free)

1 – Sheet rubber 5/8 in. thick (free)

1 – Silent traction system (STS) sheet (free)

Steps

1) Modify the transom mounting bracket by cutting off the “ears” that mount the bracket to a transom (they’re too wide to fit into the scupper hole), drilling a hole in the top of bracket to fit the square shoulder on the carriage bolt, and then use a file to square up the newly drilled hole round hole to fit the carriage bracket. File smooth/round over all sharp edges. See before and after photos.

Before

After

2) Modify the ½ x 2 S/S fender washer by making it oval rather than round to fit the scupper hole. Needs to be slightly undersized to accommodate the STS liner. Cut notch in the washer to accommodate the transducer power cable. File smooth/round over all sharp edges.

3) Modify the ¼ x 1 ¼ S/S fender washer with a notch that lines up with the one in the ½ x 2 fender washer. File smooth/round over all sharp edges. Note that two washers are required because the center hole in the ½ x 2 washer is larger the locknut.

4) “Dry fit” the transducer on the mounting bracket using the bolt and all washers supplied by Lowrance. Mark the bolt where it passes through the nut. Cut off the thread end of the Lowrance supplied bolt to shorten it enough so that it is just slightly longer than the nut. Note that anytime you shorten a bolt by cutting/filing, I recommend threading a nut or thread die onto the bolt to repair any threads damaged in the cutting process PRIOR TO making the cut. When you screw off the nut/die, it will “heal” the damaged threads. Be sure to use cutting fluid on the nut/die to eliminate binding. I also bevel the corners of the rough cut with a file/grinder before threading off the die.

5) Feed carriage bolt through square hole in mounting bracket. Head of carriage bolt is towards the transducer. Note that this needs to done BEFORE the transducer is mounted to the bracket because the transducer blocks the hole after it is fixed to the bracket.

6) Mount transducer in the bracket. Bracket orientation is “star hole” toward front of transducer and curved edge (on top) towards rear of transducer. Instead of using the recommended order for the washers as shown in the Lowrance manual, use the following order – Bolt head, S/S washer, rubber washer, transducer bracket, plastic star washer, transducer, plastic start washer, transducer bracket, rubber washer, S/S washer and locknut. This centers the ends of the bolt to help keep it from rubbing on the side of the scupper hole. Orient the transducer at 90 degrees to the carriage bolt. Tighten nut.

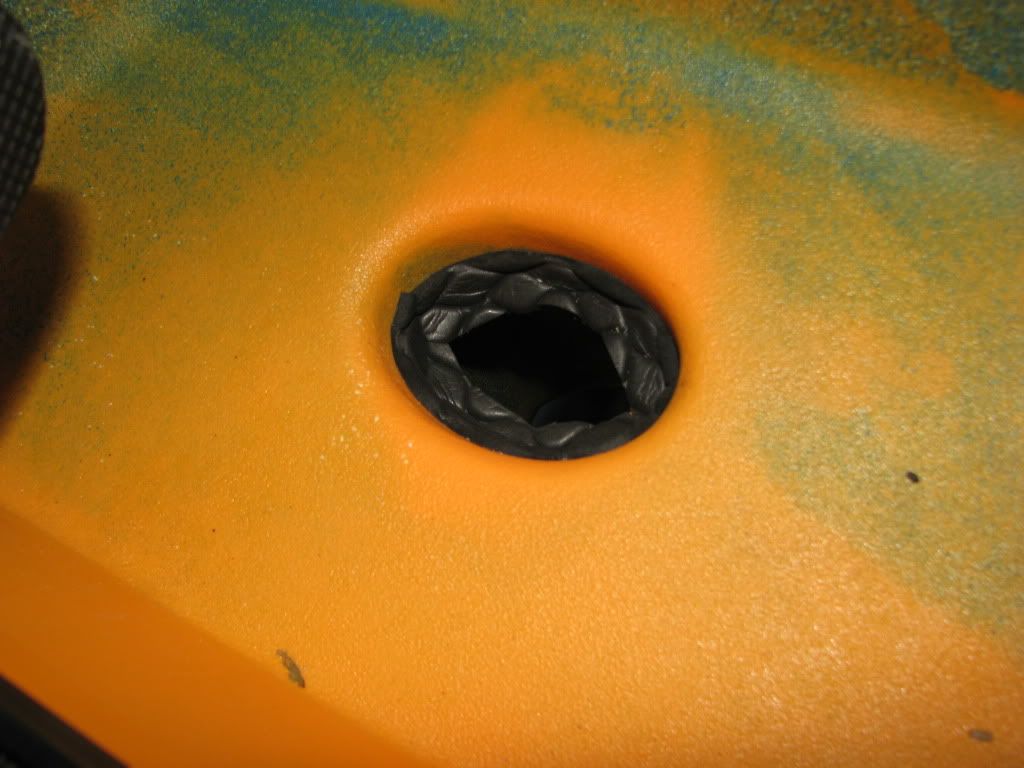

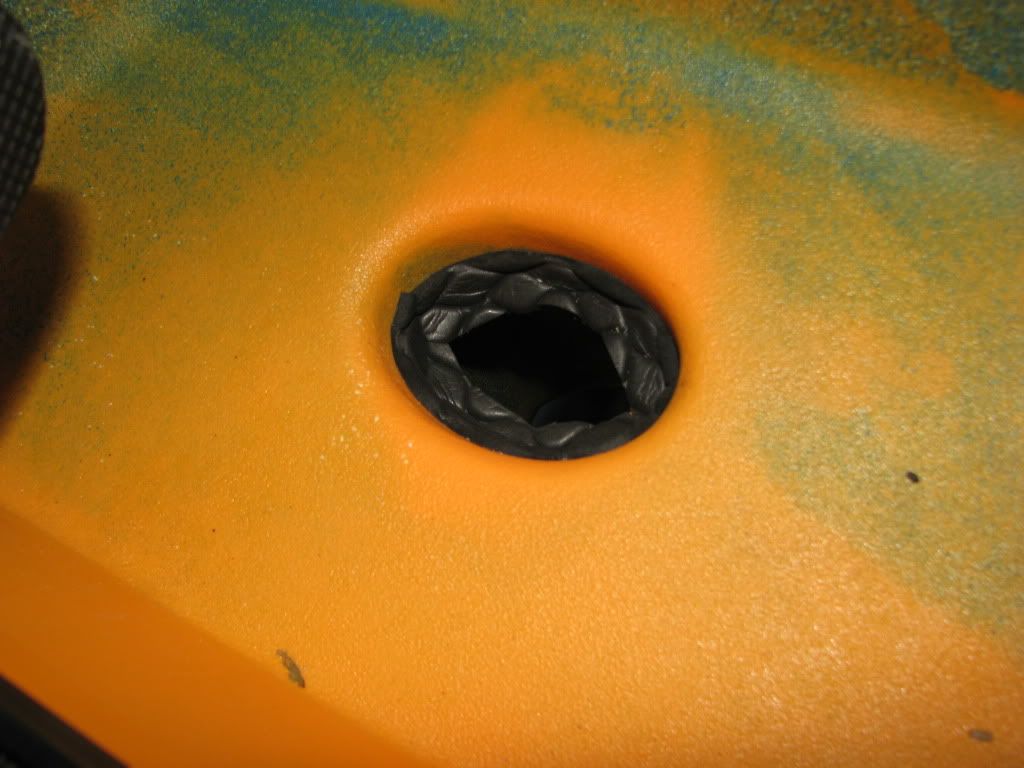

7) Line the inside/top of the scupper hole of your choosing with STS cut to fit. (I used the front hole since it’s in front of my heel). This will keep the metal washer from rubbing directly on the kayak and potentially cutting into it over time.

Scupper lined with STS

8) Cut a 2 1/8 inch long section of noodle and small diameter plastic pipe. Notch the bottom of the noodle to fit the bolt, nut and washers on the transducer mounting bracket. Cut a slot on a 45 degree angle in the front of the noodle for the transducer power wire. The bottom end of the slot should be even with front ID of noodle and the top end of slot about one inch up from the bottom on the OD. This slot will keep the power wire from contacting the transducer mounting bracket and rubbing/cutting through over time.

Pipe

9) Place the ½ x 2 S/S fender washer in scupper hole. Slide pipe over carriage bolt and feed carriage bolt from under the kayak through the fender washer and mark top of carriage bolt for trimming. I wanted to keep the top of my bolt below the top of the scupper hole. Remove assembly and cut off top of carriage bolt (see notes above on bolt cutting). Note that I used a 5 inch long carriage bolt and 4 inches would probably have worked based on the amount of bolt I cut off. I could have saved a few pennies!

10) Final install – Slide pipe over carriage bolt. Slide noodle over pipe. Align notches in noodle with bolt in transducer mount and run power wire on outside of noodle.

Subassembly from side

Subassembly from bottom

Spray outside of noodle with lubricant (it’s a tight fit in the scupper hole. I used silicon spray.). Feed power wire through scupper hole and through notch in fender washer. Feed carriage bolt through hole in fender washer. Slide assembly into place (you’ll need to push hard). Slide ¼ x 1 ¼ S/S fender washer over carriage bolt and thread ¼-20 S/S nylon lock nut onto bolt. Slice rubber grommet to get around power wire and feed into notches in washers.

From bottom

From top

11) Cover final assembly w/rubber block to “dress up”. Block will need to be cut to size & holes drilled to fit over top of carriage bolt/lock nut & power wire.

After cover

Parts

1 – Lowrance transom mount transducer

1 – Lowrance transom mounting bracket

1 – Set Lowrance bolt, nut & washers for transducer to bracket connection

1 – ¼-20x5” SS carriage bolt ($1.98 – Lowes)

1 – ½x2 SS fender washer ($0.65 – Lowes)

1 – ¼x1¼ SS fender washer ($0.65 – Lowes)

1 – ¼-20 SS nylon lock nut ($1.18 for 3 – Home Depot)

1 – Leftover Rainbird superpipe (~ ½ in. dia. x 2 1/8 in. long plastic – free)

1 – Blue pool noodle (~$2.00 – Walmart)

1 – Rubber grommet (free)

1 – Sheet rubber 5/8 in. thick (free)

1 – Silent traction system (STS) sheet (free)

Steps

1) Modify the transom mounting bracket by cutting off the “ears” that mount the bracket to a transom (they’re too wide to fit into the scupper hole), drilling a hole in the top of bracket to fit the square shoulder on the carriage bolt, and then use a file to square up the newly drilled hole round hole to fit the carriage bracket. File smooth/round over all sharp edges. See before and after photos.

Before

After

2) Modify the ½ x 2 S/S fender washer by making it oval rather than round to fit the scupper hole. Needs to be slightly undersized to accommodate the STS liner. Cut notch in the washer to accommodate the transducer power cable. File smooth/round over all sharp edges.

3) Modify the ¼ x 1 ¼ S/S fender washer with a notch that lines up with the one in the ½ x 2 fender washer. File smooth/round over all sharp edges. Note that two washers are required because the center hole in the ½ x 2 washer is larger the locknut.

4) “Dry fit” the transducer on the mounting bracket using the bolt and all washers supplied by Lowrance. Mark the bolt where it passes through the nut. Cut off the thread end of the Lowrance supplied bolt to shorten it enough so that it is just slightly longer than the nut. Note that anytime you shorten a bolt by cutting/filing, I recommend threading a nut or thread die onto the bolt to repair any threads damaged in the cutting process PRIOR TO making the cut. When you screw off the nut/die, it will “heal” the damaged threads. Be sure to use cutting fluid on the nut/die to eliminate binding. I also bevel the corners of the rough cut with a file/grinder before threading off the die.

5) Feed carriage bolt through square hole in mounting bracket. Head of carriage bolt is towards the transducer. Note that this needs to done BEFORE the transducer is mounted to the bracket because the transducer blocks the hole after it is fixed to the bracket.

6) Mount transducer in the bracket. Bracket orientation is “star hole” toward front of transducer and curved edge (on top) towards rear of transducer. Instead of using the recommended order for the washers as shown in the Lowrance manual, use the following order – Bolt head, S/S washer, rubber washer, transducer bracket, plastic star washer, transducer, plastic start washer, transducer bracket, rubber washer, S/S washer and locknut. This centers the ends of the bolt to help keep it from rubbing on the side of the scupper hole. Orient the transducer at 90 degrees to the carriage bolt. Tighten nut.

7) Line the inside/top of the scupper hole of your choosing with STS cut to fit. (I used the front hole since it’s in front of my heel). This will keep the metal washer from rubbing directly on the kayak and potentially cutting into it over time.

Scupper lined with STS

8) Cut a 2 1/8 inch long section of noodle and small diameter plastic pipe. Notch the bottom of the noodle to fit the bolt, nut and washers on the transducer mounting bracket. Cut a slot on a 45 degree angle in the front of the noodle for the transducer power wire. The bottom end of the slot should be even with front ID of noodle and the top end of slot about one inch up from the bottom on the OD. This slot will keep the power wire from contacting the transducer mounting bracket and rubbing/cutting through over time.

Pipe

9) Place the ½ x 2 S/S fender washer in scupper hole. Slide pipe over carriage bolt and feed carriage bolt from under the kayak through the fender washer and mark top of carriage bolt for trimming. I wanted to keep the top of my bolt below the top of the scupper hole. Remove assembly and cut off top of carriage bolt (see notes above on bolt cutting). Note that I used a 5 inch long carriage bolt and 4 inches would probably have worked based on the amount of bolt I cut off. I could have saved a few pennies!

10) Final install – Slide pipe over carriage bolt. Slide noodle over pipe. Align notches in noodle with bolt in transducer mount and run power wire on outside of noodle.

Subassembly from side

Subassembly from bottom

Spray outside of noodle with lubricant (it’s a tight fit in the scupper hole. I used silicon spray.). Feed power wire through scupper hole and through notch in fender washer. Feed carriage bolt through hole in fender washer. Slide assembly into place (you’ll need to push hard). Slide ¼ x 1 ¼ S/S fender washer over carriage bolt and thread ¼-20 S/S nylon lock nut onto bolt. Slice rubber grommet to get around power wire and feed into notches in washers.

From bottom

From top

11) Cover final assembly w/rubber block to “dress up”. Block will need to be cut to size & holes drilled to fit over top of carriage bolt/lock nut & power wire.

After cover